A series of knowledge related to hydraulic oil for construction machinery - contaminant analysis of oil in hydraulic system

A series of knowledge related to hydraulic oil for construction machinery - contaminant analysis of oil in hydraulic system

Oil contamination has a direct impact on the operational reliability of the system and the service life of the components.

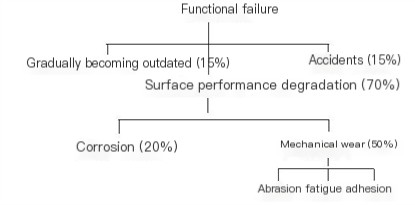

Domestic and foreign data show that the failure of the system has the following three points: 15% of the failure is caused by the obsolescence of the system, 15% is caused by accidents, and 70% is caused by oil pollution. Further analysis of this factor shows that 20% is due to corrosion and 50% is due to mechanical wear. The reason for this is that the failure is mainly caused by the presence of various solid particles, water and air in the oil.

1. Classification of hydraulic system oil pollutants

The pollutants in the system can be divided into the following according to the form in which they exist:

Solid pollutants such as copper chips, iron dust, mineral fines, dust

Liquid contaminants such as water

Gaseous pollutants such as air, chlorine, carbon monoxide

The above three states of pollutants may be transformed into each other when the environment changes, and these pollutants also produce chemical reactions when they exert mechanical forces.

1) Solid particles

Solid particles are the number one factor causing mechanical wear and tear and are the main object of pollution control research.

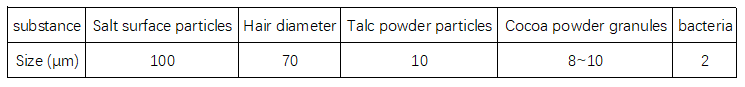

Solid particles are substances that are measured in microns, the smallest particle size visible to the naked eye is 40 μm, and some of the different types of tiny solid particle size ranges are shown in the table below:

As can be seen from the above example, the contamination of solid particles in the oil that is invisible to the naked eye is abundant. For the detection of these solid particle contaminants, there are NASA1638 international standards.

NAS 1638 is a cleanliness specification proposed by NASA in 1964, which is still in use today and is widely recognized by industries around the world.

2) Oxidation of the oil

The oxidation of oil is the main reason for the scrapping of lubricating oil, and the oxidized part of the waste lubricating oil accounts for 4%-5% of the total oil, and the components generated by oxidation can be separated under the purification action of the vacuum centrifuge. However, when the oil is oxidized, there is already a loss of oil if it is purified. Through online real-time purification, the pollutants of the oxidized oil can be removed at any time to ensure the normal use of the oil to the greatest extent.

Water and air in the oil, as well as heat energy, are necessary conditions for oil oxidation, and metal particles in the oil play an important catalytic role in oil oxidation. Experimental studies show that when there are metal particles and water in the oil at the same time, the oxidation rate of the oil increases sharply, and the catalytic action of iron and copper increases the oxidation rate of the oil by more than 10 times and 30 times, respectively.

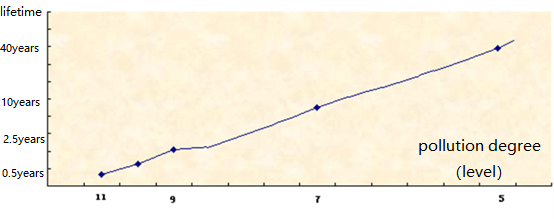

When research institutes around the world study the effects of pollution on life, the results vary widely, mainly due to factors such as working environment, pollutant composition and particle hardness. Generally speaking, by NAS1638 standard, the level of contamination is reduced by one level, the life span is doubled, and vice versa. Assuming that the life of the machine is 10 years with a pollution level of 7 (NAS1638), the same machine reduces the pollution level of the oil by several levels, and the life of the machine changes dramatically.

3) Air

Air can exist in the oil in two forms: dissolved or free. Air dissolved in the liquid has less impact on the system, but once separated from the liquid, it becomes a bubble, which reduces system performance, reliability and component life. The specific hazards of free air in the liquid to the system are as follows:

※Air can produce cavitation, which aggravates the erosion and damage of the surface of the component material;

※ Make the operation response of the equipment sluggish and unstable, and increase the power consumption;

※Accelerate oil oxidation, reduce lubrication performance, and increase oil acid value;

※Reduce the volumetric elastic modulus and stiffness of the oil;

※Increase the noise of the equipment operation;

※ Increase the temperature and increase the leakage

4) Moisture

Water can also be present in the oil in two forms: dissolved or free. Water is a serious pollutant in the system, and people often don't pay enough attention to it. The biggest hazard of water to the system is corrosion, and other aspects are the production of oxides, dirt and gels.

Water corrosion can reduce the surface properties of components and allow rust particles to enter the system; The interaction of water and additives will produce harmful substances and accelerate the deterioration of oil;

The synthesis of acidic products from water and oxides leads to changes in fluid properties; Water mixed into the oil can emulsify the oil and reduce its lubricating properties; At low temperatures, water freezing can also cause system failure, which can be affected like small sand particles or small metal particles, blocking the flow channel and holes, damaging the surface, and failing to function the components.

Water promotes the growth of microorganisms; The coexistence of water and metal particles will significantly shorten the oxidation time of the oil and increase the acid number of the oil in use.

2. The source of pollutants

There are three main aspects of how these various pollutants can enter the system:

One is the residual contaminants of the new system, which are left in the system when the components and pipes are assembled

second, it is generated in the process of mechanical wear and oil oxidation in the work;

The third is to enter the system in the use and maintenance of the equipment.

3. The generation mechanism of pollutants

From the perspective of the source of contaminants, excluding the unavoidable factors in maintenance and operation, the most important contaminants are generated due to mechanical wear and chemical abrasion during the operation of the equipment.

Mechanical wear can be divided into: abrasive wear, adhesive wear, fatigue damage.

Chemical abrasion can be divided into: chemical corrosion and fluid deterioration.

Particulate matter generation:

Mechanical wear and tear

One of the abrasive wear: frictional wear

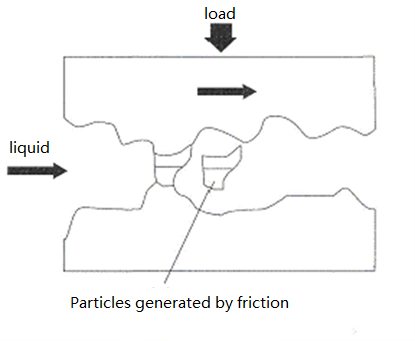

In the process of friction of mechanical parts, particles of similar or slightly larger size to the dynamic gap are the most dangerous, and they cut the surface material; This makes the gap size change and produce more particles. As shown in the figure below

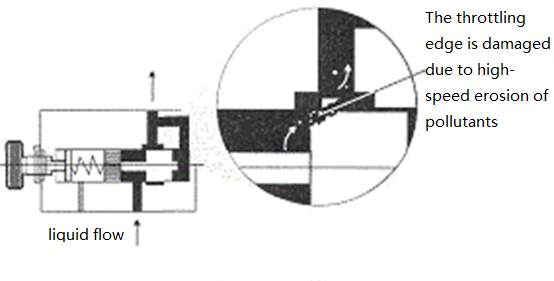

Abrasive wear 2: erosion wear

When the medium flows, especially under the condition of high-speed flow, the particles impact the edge and surface of the part at high speed, causing the surface material to peel off due to the momentum effect, so that the shape of the part and the gap between the parts change, and more particles are produced at the same time. As shown in the figure below

Adhesive wear

Heavy loads, slow speeds, or low viscosity of the oil can reduce the film thickness, resulting in direct metal-to-metal contact and certain raised surfaces bonding together. When adjacent faces move, these bonding points are sheared to produce metal particles. As shown in the figure below