A series of knowledge related to hydraulic oil for construction machinery - the classification and use requirements of hydraulic oil

A series of knowledge related to hydraulic oil for construction machinery - the classification and use requirements of hydraulic oil

According to authoritative data, 70% of the failures of construction machinery are caused by hydraulic systems. More than 75% of hydraulic system failures are caused by hydraulic fluid contamination. Therefore, the pollution of hydraulic oil and its control must be paid great attention.

1. Classification and requirements for hydraulic oil

Construction machinery hydraulic oil is divided into ordinary hydraulic oil, anti-wear hydraulic oil, low condensation hydraulic oil, high viscosity index hydraulic oil, special hydraulic oil, mechanical oil and gas turbine oil.

Hydraulic oil should have suitable viscosity and good viscosity temperature characteristics, and high viscosity index; The oil film has high strength and good lubricating properties; Good chemical stability and strong antioxidant capacity; Good anti-rust and anti-corrosion ability, good adaptability to coatings, sealing materials, etc., good demulsification resistance and defoaming, high flash point, low freezing point, pure and no impurities.

2. The range of use of various hydraulic oils

(1) Ordinary hydraulic oil is divided into YA-N46, YA-N68, YA-N150, YA-N32G and YA-N68G and other grades.

It is suitable for all kinds of medium and high pressure systems with an ambient temperature of 0-40. (The applicable working pressure is 6.3-21Mpa)

(2) Anti-wear hydraulic oil is divided into YB-N32, YB-N46, YB-N68, YB-N80, YB-N100, YB-N150 and YB-N46K.

It is suitable for high-pressure systems with ambient temperatures of -10-40. (The applicable working pressure is >21Mpa)

(3) Anticoagulant hydraulic oil is divided into grades.

It is suitable for high-pressure systems with ambient temperatures of -20-40. (Applicable working pressure up to 21Mpa) of which YC-N46D can be used for - more than 30, mainly used in mining, construction machinery and other hydraulic systems.

(4) Machinery oil is divided into HJ-10, HJ-30, HJ-40, HJ-50, HJ-70, HJ-90 and other grades.

It can be used as a substitute oil for hydraulic systems, suitable for systems with working pressure less than 6.3Mpa, and the applicable ambient temperature is 0-40.

(5) Gas turbine oil is divided into Hu-20, Hu-30, Hu-40, Hu-50, Hu-55 and other grades.

It can be used as a substitute oil for hydraulic system, because of the addition of antioxidant additives, its quality is better than that of mechanical oil, and it is suitable for hydraulic systems with higher requirements for working pressure less than 6.3Mpa.

(6) There are two kinds of high viscosity index hydraulic oil: YD-N32 and YD-N32H, which are mainly used in systems with special requirements for oil viscosity and temperature characteristics.

3. Selection of hydraulic oil

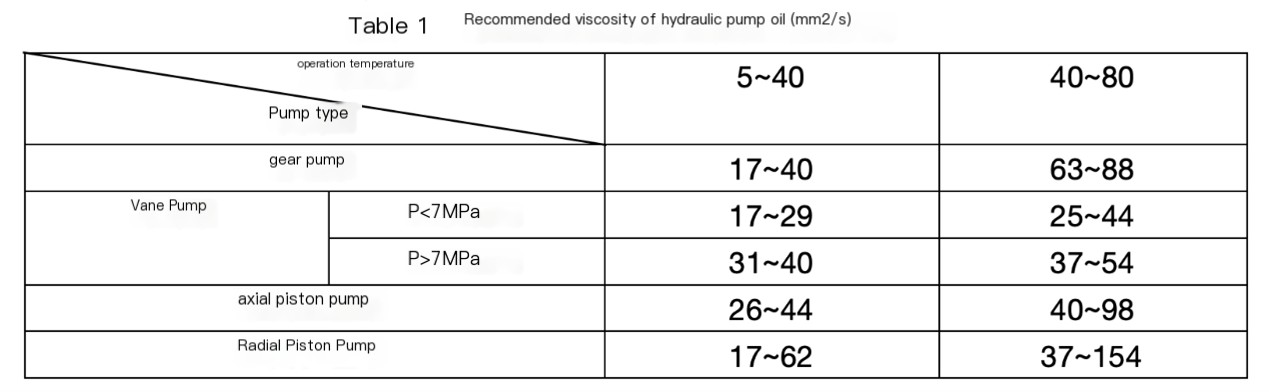

(1) Select the appropriate viscosity hydraulic oil according to the type of hydraulic pump used Table 1 gives the recommended values for the viscosity of several hydraulic pump oils.

(2) Considering the ambient temperature, working pressure, speed of the actuator and other use conditions, the hydraulic oil with suitable viscosity can be selected.

If the ambient temperature or pressure is high, the hydraulic oil with high viscosity is used; When the ambient temperature or pressure is low, a hydraulic fluid with a bottom viscosity is used.

When the working temperature is below 60 and the load is light, mechanical oil can be selected, and when the working temperature is more than 60, gas turbine oil or ordinary hydraulic oil should be used; When the working pressure is high or high, anti-wear hydraulic oil is used.

If the equipment is started at a very low temperature (such as construction machinery working in the open air in winter), low-condensation hydraulic oil is used.

When the actuator speed is very high, it is advisable to use low viscosity hydraulic oil.