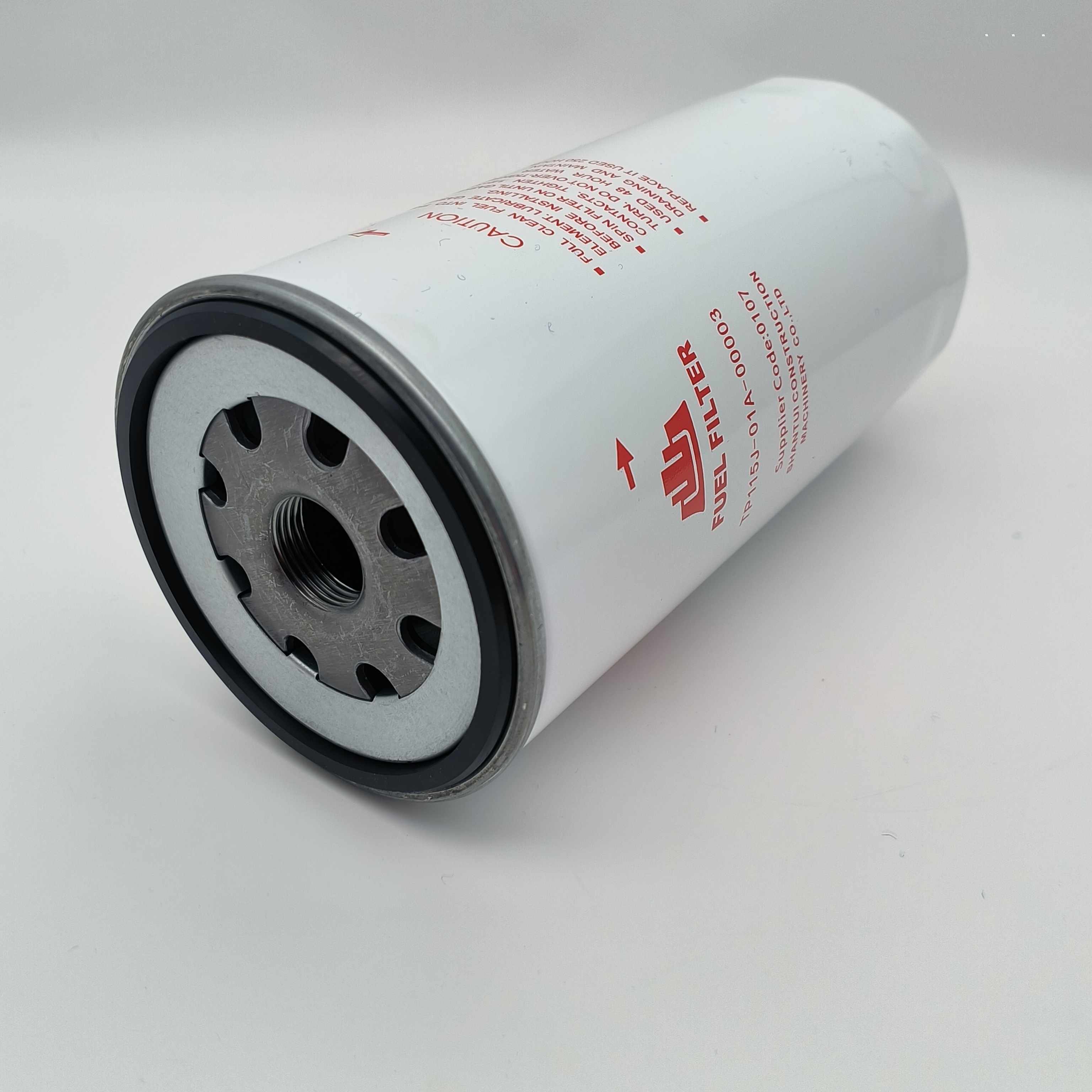

Fuel Filter Element

Filter medium: German imported glass fiber composite layer (including stainless steel support mesh)

Filtering accuracy: β ₅ (c)=200 (tested according to ISO 16889:2017 standard)

Working pressure range: 0.2-1.5MPa (peak pressure resistance 2.0MPa)

115J-01A-00003 is a specialized fuel filter element designed for heavy-duty construction machinery, primarily used in bulldozers to ensure optimal engine performance and longevity. Based on available information, its key attributes are summarized below.

Product Characteristics

High-Efficiency Filtration: Engineered to remove contaminants from fuel, protecting critical engine components from wear and damage.

Material Durability: Constructed with robust materials to withstand harsh operational environments, including extreme temperatures and pressures.

Compatibility: Specifically designed for Shantui bulldozer models such as DH46 and DH24, ensuring precise fit and function.

Advantages

Enhanced Engine Protection: Prevents fuel system clogs and extends engine lifespan by trapping fine particulate matter.

Cost-Effective Maintenance: Reduces downtime and repair costs through reliable filtration, minimizing unplanned equipment failures.

Ease of Installation: Simplified design allows for quick replacement during routine maintenance, saving labor time.

Application Scenarios

Construction Sites: Deployed in bulldozers for earthmoving, excavation, and road-building projects, where fuel purity is critical for continuous operation.

Mining Operations: Used in heavy machinery operating in dusty or abrasive environments to maintain fuel system integrity.

Industrial Maintenance: Integral to fleet management programs for regular servicing of Shantui bulldozers and similar equipment.

Parameters

115J-01A-00003 Industrial Filter Cartridge is a high-performance filtration solution designed specifically for harsh industrial environments. This product adopts an innovative multi-layer composite filter material structure, which maintains a high filtration efficiency of 98.5% while possessing excellent temperature resistance and quick disassembly characteristics. Its significant advantages include: reducing maintenance costs by 40%, reducing equipment related failures by 62%, and supporting replacement operations within 5 minutes. Mainly used in key fields such as hydraulic systems of construction machinery, lubrication systems of industrial production lines, and oil circulation systems of wind power equipment, it meets international standards and is recommended to maintain for 2000 hours or replace according to pressure differential indications.