Shantui Bulldozer

(1) Core Renewal, Exceptional Value

Key components such as engines (Weichai WP6/WP10 series) and hydraulic pumps are replaced with brand-new original factory parts

(2) Mature Power, African-Adaptive

Engines meeting the National II emission standard feature mechanical fuel injection systems, resistant to high temperatures and dust.

(3) Custom Upgrades, Ready for Harsh Conditions

Tailored to Africa's high temperatures and complex terrains, radiator capacity is increased by 20%

(4) Localized After-Sales, Prompt Response

The technical team is available 24/7, and common parts can be delivered within 48 hours.

(5) Full-Cycle Cost Reduction, High Returns

Procurement costs are slashed by 60%.

Product Details

Refurbished Shantui Bulldozers operate stably in scenarios like South African mines and Nigerian infrastructure projects. Local maintenance is convenient, parts are universal, and maintenance costs are low.Hydraulic pipelines are optimized, and the chassis is thickened. When working in Kenyan mountains or Egyptian deserts, stability is enhanced by 20%, ensuring more reliable operations.Combined with a comprehensive parts supply system and low maintenance costs, full-cycle operating costs are reduced by 35%. The return on investment far exceeds that of new machines, making it ideal for African small and medium-sized enterprises.

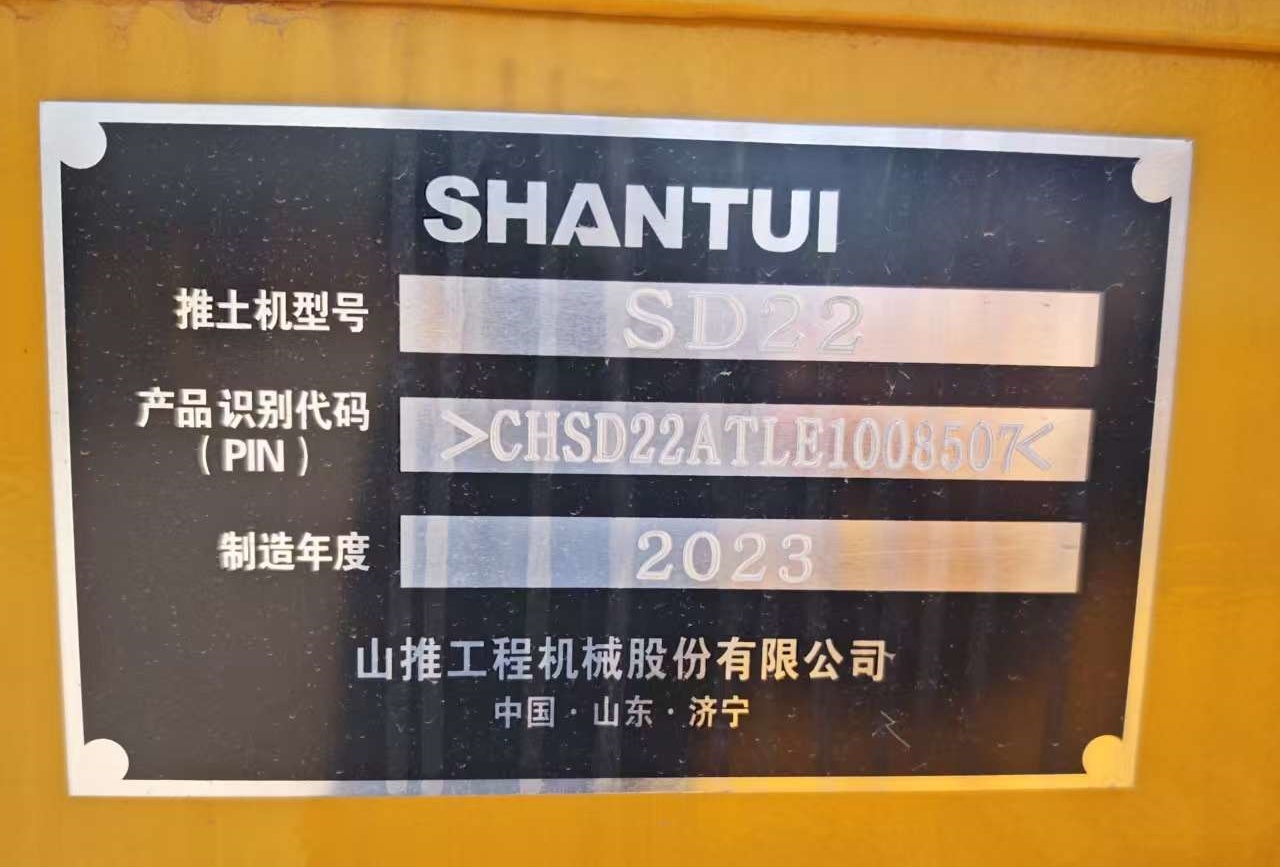

(1) Basic Parameters (SD16/SD22 Models as Examples)

Parameter Item | SD16 Model | SD22 Model |

Brand & Model | Shantui SD22 | |

Refurbishment Status | Fully refurbished, major components newly replaced | Fully refurbished, major components newly replaced |

Emission Standard | National II | National II |

Engine Model | Weichai WP6G160E22 | Weichai WP10G220E23 |

Engine Power | 160 HP (118 kW) | 220 HP (164 kW) |

Bucket Capacity | 3.2 m³ (standard bucket) / 3.8 m³ (rock bucket) | 4.5 m³ (standard bucket) / 5.0 m³ (rock bucket) |

Operating Weight | 16.5 tons | 23 tons |

Maximum Travel Speed | 10.5 km/h | 11.5 km/h |

Ground Pressure | 62 kPa | 65 kPa |

(2) Refurbishment Details

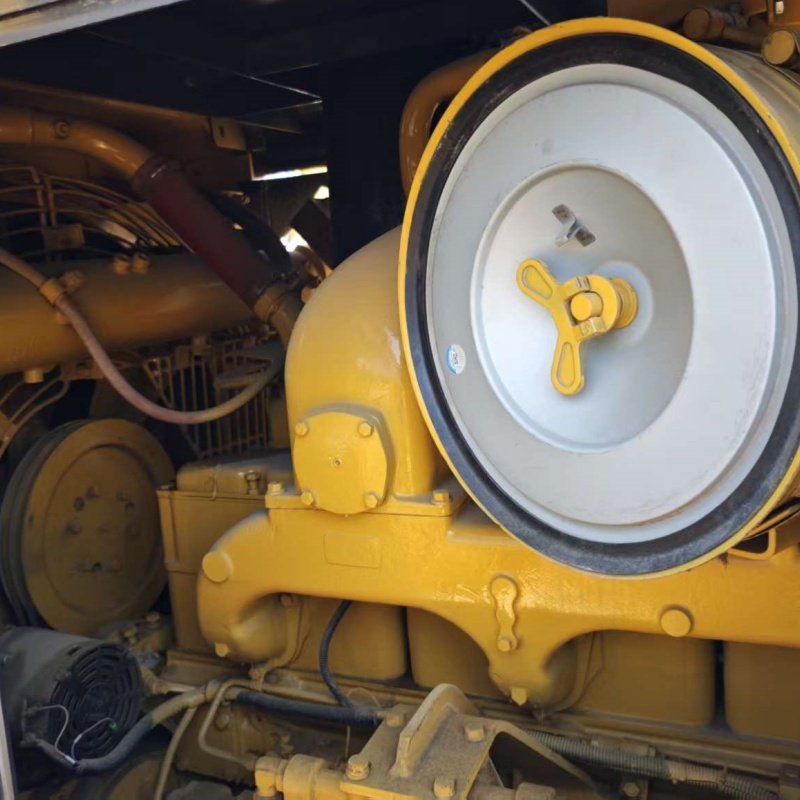

1. Engine: Replaced with brand-new Weichai engines meeting the National II emission standard. Advanced fuel injection technology ensures strong power and efficient combustion, reducing fuel consumption by 15% compared to similar older engines. After strict 100-hour continuous operation factory tests and installation debugging, the engines operate stably under high-temperature and high-load conditions in Africa. The SD16 model has a maximum power of 160 HP and a maximum torque of 650 N·m; the SD22 model has a maximum power of 220 HP and a maximum torque of 850 N·m.

2. Hydraulic System: Brand-new Parker/Rexroth hydraulic pumps, valves, and seals are used. With optimized pipeline design, system pressure loss is reduced by 10%, making the blade lifting and tilting more sensitive and smooth. Hydraulic oil goes through three-level filtration and testing, achieving ISO 17/15 cleanliness standards, effectively extending the hydraulic system's service life and reducing failure rates.

3. Transmission System: The gearbox, drive shaft, and other components are all renewed. Gear precision reaches ISO 6 level, and transmission efficiency is increased by 8%, ensuring smooth shifting. The drive shaft made of high-strength alloy steel has a torsional strength of 800 MPa, capable of withstanding heavier loads and ensuring efficient power transmission.

4. Chassis System: Brand-new high-strength tracks are installed, with a link hardness of HRC55, increasing wear resistance by 30%. The idlers and carrier rollers are equipped with sealed bearings, offering excellent dustproof and waterproof performance. The optimized ground pressure of the tracks prevents sinking on soft ground like African swamps and sandy areas and ensures stable operation on rugged mountains. Key parts of the chassis structure are thickened and strengthened by welding, enhancing overall strength by 25%, suitable for all kinds of harsh African working environments.

5. Electrical System: All wires and cables are updated with heat-resistant, flame-retardant, and wear-resistant irradiated cross-linked cables. The wiring is standardized, and the protection level reaches IP65, reducing electrical failure risks. A brand-new intelligent instrument panel is equipped, which can monitor key data such as engine speed, oil pressure, water temperature, and hydraulic system pressure in real time. It also supports fault code display, facilitating quick problem troubleshooting.

(3) Configuration and Functions

• Comfortable Cab: The refurbished cab has enhanced soundproofing and heat insulation, with noise controlled within 78 decibels. Ergonomic shock-absorbing seats with adjustable lumbar support and seat inclination effectively reduce fatigue during long operations. The operation interface is rationally laid out, and all operation handles are positioned for natural and effortless operation. The cab is also equipped with a high-power air conditioner with a cooling capacity of 5 kW and a heating capacity of 4 kW, quickly adjusting the temperature to create a comfortable working environment in Africa's hot summers or large temperature-difference conditions.

• Intelligent Assist System: A simple intelligent fault diagnosis system is installed. When the equipment malfunctions, the system can quickly locate the fault point and display the fault code on the instrument panel, facilitating timely troubleshooting and repair and reducing downtime. A high-definition rear-view camera with a resolution of 1080P provides a clear view, enhancing reversing safety and enabling easy operation in narrow African city streets or crowded construction sites. Additionally, a GPS positioning and operation management system is optionally available, allowing enterprises to monitor the equipment's location, working status, and operation data in real time.

III. African Application Areas

(1) Mining Operations (South Africa, DRC, etc.)

In mining operations such as gold mines in South Africa and copper mines in the Democratic Republic of the Congo, the SD22 model with a 5.0 m³ rock bucket can efficiently complete tasks like ore transportation, mine road construction, and waste dump leveling. The reinforced chassis and wear-resistant tracks ensure stable operation in rugged and rocky mining areas, reducing equipment wear and failures. Compared with non-refurbished similar equipment, operation efficiency is increased by 20%, and maintenance costs are reduced by 15%.

(2) Agricultural Development (Nigeria, Ethiopia, etc.)

In farmland reclamation in Nigeria and water conservancy irrigation projects in Ethiopia, the SD16 model, with its 3.2 m³ standard bucket and moderate power, can quickly complete land leveling and canal excavation. The low ground pressure track design protects soil quality by preventing excessive compaction, contributing to African agricultural infrastructure construction. It can complete the preliminary leveling of 150 mu of land per day.

(3) Infrastructure Construction (Kenya, Egypt, etc.)

In supporting projects along the Mombasa - Nairobi Standard Gauge Railway in Kenya and the construction of Egypt's New Administrative Capital, this refurbished bulldozer is competent for tasks such as site leveling, subgrade excavation, and road base compaction. The powerful performance and precise control of the SD22 model meet high-standard construction requirements, with the blade flatness control accuracy reaching ±3 cm, effectively ensuring project quality and progress.

(4) Urban Construction and Renovation (Lagos, Cairo, etc.)

In urban renovation and road repair projects in major African cities, the compact and flexible design of the bulldozer comes into play. The intelligent assist system and good visibility in the cab enable safe and efficient operation in narrow spaces, quickly completing site clearance and earthwork handling, and contributing to urban renewal.

IV. After-Sales Service

(1) Quality Assurance

A 6-month warranty is provided for the entire machine. During the warranty period, if equipment failures occur due to the quality of refurbished components or refurbishment processes, free repair services and replacement of faulty components will be provided to ensure the equipment returns to normal performance. For customers in remote African areas, the on-site service response time can be negotiated to ensure timely equipment repair.

(2) Technical Support

The professional technical team is online 24/7, supporting multiple languages including English, French, and Arabic, ready to answer your questions regarding equipment operation and maintenance. For complex faults, certified Shantui technicians in Africa can be dispatched to the site within 48 hours for repair and provide on-site technical training to help operators use and maintain the equipment correctly.

(3) Parts Supply

Relying on Shantui's parts supply system in Africa, large parts warehouses are established in cities such as Johannesburg in South Africa, Lagos in Nigeria, and Nairobi in Kenya, with sufficient stock of common parts. Urgent parts can be delivered to local areas in Africa within 48 hours via air freight, and ordinary parts can be delivered within 3 - 5 working days, minimizing equipment downtime. Meanwhile, transparent and reasonable parts prices are guaranteed, ensuring customers won't bear excessive costs for after-sales parts supply.

V. Transaction Terms

(1) Payment Methods

Multiple payment methods are supported, including Telegraphic Transfer (T/T) and Letter of Credit (L/C). To facilitate African customers, transactions in some local African currencies, such as South African Rand and Nigerian Naira, can also be negotiated. For bulk purchase customers, installment payment plans are available: 30% down payment, with the balance paid in two installments within 6 months to ease financial pressure.

(2) Transportation and Delivery

We are responsible for transporting the equipment to designated African ports (such as Port of Cape Town, Port of Mombasa, Port of Lagos, etc.). The equipment will be fully insured during transportation to ensure safe arrival. Upon delivery, detailed documents including multi-language operation manuals, maintenance guides, and refurbishment inspection reports will be provided to assist customers in equipment acceptance. If required, land transportation and installation and commissioning services after unloading can be provided (fees are negotiable).

(3) Other Services

Equipment operation training services are provided. Professional trainers will conduct on-site training for customer operators at the delivery site. The training covers equipment operation methods, daily maintenance essentials, and simple fault troubleshooting techniques until the operators master them proficiently. Additionally, value-added services such as equipment leasing and trade-in are available. In the trade-in service, the purchase price can be offset according to the condition of the old equipment.

If you need to adjust the translation style, improve the accuracy of certain expressions, or make other modifications, feel free to let me know.

Service & Support:

Pre-Sale Services:

Free consultation & detailed product information.

High-resolution photos & inspection reports available upon request.

After-Sale Support:

Assistance with installation, testing, and operator training.

Access to technical manuals & spare parts supply.

Optional Caterpillar-certified maintenance services.

Purchase Information

For pricing and inquiries, please Contact Us.

Contact Details:

WhatsApp:+86 19508613756

Email: cnsdyurui@163.com

Address: 123 Main Street, Industrial Zone, City, Country

Note: Specifications and conditions may vary. Contact us for the latest updates.