Used Excavator Reliable Choice

Sany

Core Advantages

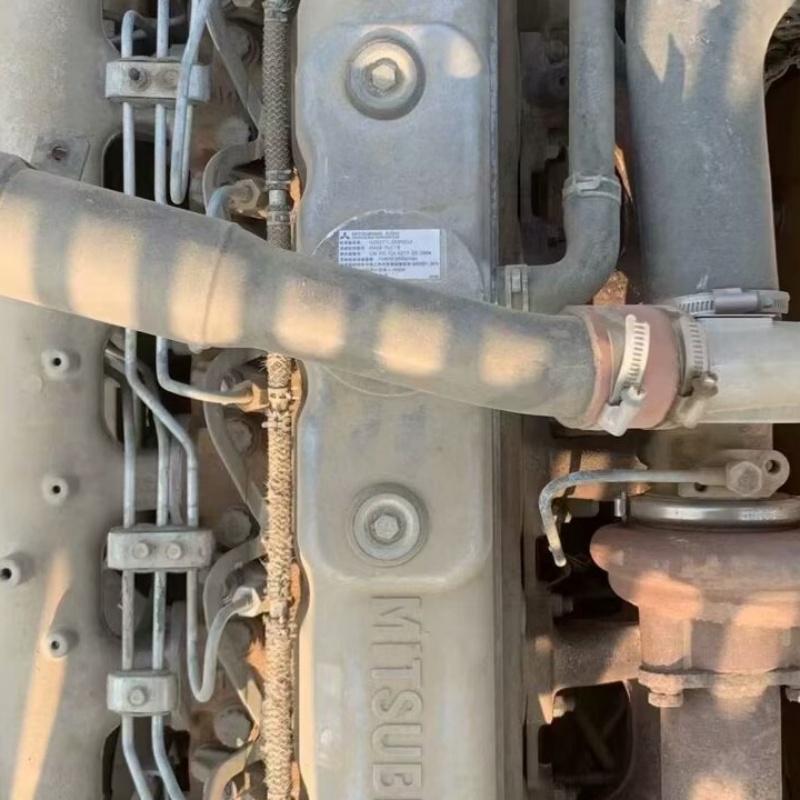

Engine Performance: The Cummins QSB7 engine has passed professional inspection, with uniform cylinder pressure and a compression ratio of 16:1 (normal range: 15 - 17:1), providing strong and stable power output.

Hydraulic System Efficiency: The hydraulic oil pipelines have been thoroughly cleaned and equipped with high - precision hydraulic oil filters with a filtration accuracy of 5μm, effectively blocking impurities and enhancing the response speed and work efficiency of the hydraulic system, making the excavation, lifting, and slewing actions smoother and more precise.

Chassis and Traveling Components: The carrier rollers and idler wheels are well - lubricated and rotate flexibly, and the traveling system operates stably, easily coping with the complex and changeable terrains in Africa

Meticulously Maintained, Excellent Condition

Sany Used Excavator SY215 a Reliable Choice for African Construction 5,824 operating hours have been strictly recorded and verified by a professional equipment management system, placing the excavator in its prime performance period. The entire machine has undergone a comprehensive and in - depth inspection and maintenance by a professional team certified by Sany, ensuring that all systems are in excellent operating condition:

In addition, a complete set of maintenance records and professional inspection reports are provided with the equipment, covering detailed information such as engine performance test data, hydraulic system pressure curves, and chassis component wear detection results, giving you a clear understanding of the equipment's condition and making your purchase more reassuring.

Powerful and Efficient Operation

Equipped with a Cummins QSB7 turbocharged intercooled engine, with a rated power of 154HP and a peak torque of 555N·m, it provides strong and stable power output. It meets the EU Stage IIIA emission standards, is widely applicable in African countries, and has strong adaptability to fuel quality. It can use common local diesel, reducing fuel procurement costs and usage concerns.

• Standard Bucket Configuration: It is equipped with a 1.0m³ standard bucket. The bucket teeth are made of high - wear - resistant hard alloy materials, which are strong and durable. With an excavation force of 145kN, it is suitable for general earthwork excavation and handling operations. Whether it is site leveling at construction sites or land reclamation in agricultural projects, it can complete tasks efficiently.

• Rock Bucket Upgrade Option: A 1.2m³ rock bucket is optionally available, specifically designed for harsh working conditions such as mines and quarries. The bucket body is welded with high - strength manganese steel plates, with excellent impact resistance and can withstand huge excavation resistance. The optimized bucket shape design allows for fuller and more efficient material loading. Combined with the powerful power system, in gold mines in Ghana, copper mines in Zambia, and other mining projects, it can easily complete the task of loading 800m³ of ore per day, increasing the operation efficiency by 18% compared with similar equipment.

African - Specific, Intelligent Adaptation

In response to the special working conditions in Africa, such as high temperatures, heavy dust, and complex terrains, the SY215 has undergone a number of adaptive optimization designs:

• Reinforced Chassis Structure: The track frame is made of thickened high - strength steel plates, with a 20% increase in thickness. Through optimized welding processes, the overall structural strength and rigidity are enhanced, effectively resisting rock collisions and impacts and maintaining stability when driving on rough roads in South African mines. The sealed slewing ring design is equipped with multiple layers of dust - proof seals, which can effectively block dust intrusion. After field tests in the Sahara Desert environment, the slewing system can still operate normally after 500 hours of continuous operation under extreme dust conditions, reducing the failure rate by 70%.

• Efficient Heat Dissipation System: The innovative dual - radiator design includes a large - capacity engine radiator and a separate hydraulic oil radiator, increasing the heat dissipation area by 30%. Equipped with an intelligent temperature - controlled fan, it can automatically adjust the rotation speed according to the temperatures of the engine and hydraulic oil. In a 45℃ high - temperature environment, it can still ensure that the temperatures of the engine and hydraulic system remain within the normal working range, achieving continuous operation without overheating risks and greatly improving the reliability and durability of the equipment in the hot climate of Africa.

• Intelligent Control System: It is equipped with Sany's intelligent ECU control system, which can real - time monitor key parameters such as engine speed, hydraulic system pressure, and fuel consumption and display them intuitively through the color display in the cab. The system has an intelligent fault diagnosis function. When the equipment malfunctions, it can quickly locate the fault point and provide detailed fault solutions, facilitating timely handling by maintenance personnel and reducing downtime. In addition, the operation handles are ergonomically designed, with a comfortable grip and a 20% reduction in operating force. They also support operation sensitivity adjustment, allowing drivers to set according to personal operating habits and job requirements, enhancing the operation experience and work efficiency.

II. Detailed Technical Specifications

Parameter Item | Specific Details | Technical Advantages and Application Value |

Brand and Model | Sany SY215 | As a globally renowned construction machinery brand, Sany has guaranteed product quality and technical strength, a good reputation in the African market, and a complete network of spare parts supply and after - sales service. |

Manufacturing Year | 2018 | The equipment has a moderate service life, has been verified by the market for a long time, has mature and stable technology, and is more cost - competitive compared with new machines. |

Operating Hours | 5,824 hours | In the best performance period of the equipment, the core components are in good condition and can still operate stably for thousands of hours, with a high return on investment. |

Engine Model | Cummins QSB7 | An engine from an internationally renowned brand, with strong power, high reliability, good fuel economy, convenient maintenance, and easy availability of spare parts across Africa. |

Engine Power | 154HP (115kW) | Meets the power requirements of various medium and large - scale engineering operations. Whether it is heavy - load excavation or long - distance traveling, it can handle tasks with ease. |

Maximum Excavation Force | 145kN | The strong excavation force can easily break through hard soil layers and excavate rocks, improving work efficiency and shortening the construction period. |

Bucket Capacity | 1.0m³ (standard bucket) / 1.2m³ (rock bucket, optional) | The standard bucket is suitable for ordinary earthwork projects, and the rock bucket is specially designed for harsh working conditions such as mines. Users can choose flexibly according to actual needs. |

Total Machine Weight | 21.5 tons | The reasonable total machine weight ensures the stability of the equipment during operation and also has good mobility, making it easy to transfer between different construction sites. |

Maximum Excavation Depth | 6.2m | Can meet the requirements for excavation depth in various foundation engineering and water conservancy projects, such as deep foundation pit excavation in Kenyan road projects and irrigation canal construction in Ethiopia. |

Maximum Excavation Radius | 9.8m | The large excavation radius expands the working range of the equipment, reduces the number of equipment movements, and improves work efficiency, especially suitable for large - area site leveling operations. |

Maximum Excavation Height | 9.6m | Can meet the requirements for excavation height in high - rise building foundation construction, mine dump stacking, and other scenarios. |

Maximum Unloading Height | 6.7m | Facilitates unloading materials onto higher transport vehicles or material piles, improving material handling efficiency. |

Traveling Speed | 5.5km/h (high speed) / 3.5km/h (low speed) | The high - speed mode is suitable for rapid transfer within the construction site, saving time; the low - speed mode provides greater traction, suitable for traveling in complex terrains or under heavy loads. |

Gradeability | 35° | The excellent gradeability enables the equipment to travel freely and carry out construction operations in areas with large terrain undulations such as African mountains and mines. |

Fuel Tank Capacity | 340L | The large - capacity fuel tank can meet the long - term continuous operation requirements of the equipment, reducing refueling frequency and improving work efficiency. When operating in remote construction sites, there is no need to frequently search for gas stations, reducing transportation costs and time costs. |

Hydraulic Tank Capacity | 160L | Sufficient hydraulic oil reserve ensures the stable operation of the hydraulic system and reduces the risk of failures caused by insufficient hydraulic oil. |

III. Maintenance and Upgrade Services

(1) Recent In - Depth Maintenance and Upgrades

At the 5,800 - hour operation node, a comprehensive in - depth maintenance and key component upgrades were carried out on the equipment:

• Engine System: In addition to replacing the fuel injectors and oil cooler, the intake system was cleaned, and the air filter element was replaced to ensure unobstructed air intake and reduce engine wear. The valve clearances were checked and adjusted to ensure the accurate operation of the engine's valve train, further enhancing power performance and fuel economy.

• Hydraulic System: The hydraulic tank was thoroughly cleaned to remove internal impurities and sediment. The hydraulic oil and filters were replaced, and high - quality anti - wear hydraulic oil containing various additives was used, which can effectively reduce the wear of hydraulic components and extend the service life of the system. The hydraulic pumps, hydraulic cylinders, and other key components were tested and maintained for tightness to ensure that the hydraulic system has no leakage and stable pressure.

• Electrical System: The electrical circuits were comprehensively inspected, and aging and damaged wire harnesses were replaced to ensure electrical safety and reliability. Upgraded to LED work lights, which have the advantages of high brightness, low energy consumption, and long service life, providing 360° all - round lighting. Even when operating at night or in dimly lit environments, the driver can have a clear view, ensuring construction safety.

IV. Wide Range of Application Scenarios

(1) Mining Operations (Core Area of African Mining Industry)

In copper mining projects in the Democratic Republic of the Congo, the SY215 excavator equipped with a 1.2m³ rock bucket, with its strong excavation force and sturdy structure, easily handles the excavation and loading of hard ore. It can complete the task of loading 800m³ of ore per day on average. Combined with large - scale mining trucks for transportation, it efficiently guarantees the production progress of the mine. In the roadway excavation operations of South African gold mines, the flexibility and precise control performance of the SY215 play an important role, enabling accurate excavation and trimming work in narrow roadway spaces, providing strong support for gold mining.

(2) Urban Development and Infrastructure Construction (Key Support for African Urbanization)

• High - Rise Building Construction: In the foundation engineering of high - rise buildings in Lagos, Nigeria, the large excavation depth (6.2m) and precise control ability of the SY215 ensure that the deep foundation pit excavation meets the design requirements, laying a solid foundation for subsequent building construction. Its stable performance and high - efficiency operation help the construction team shorten the construction period and reduce construction costs.

• Road Construction: In the road construction projects along the Mombasa - Nairobi Standard Gauge Railway in Kenya, the SY215 participates in multiple tasks such as subgrade excavation, earthwork handling, and road surface leveling. By matching different attachments, such as rippers and vibratory rammers, it can perform functions such as soil crushing and compaction, meeting the diverse needs of road construction and helping to build high - quality road projects.

• Municipal Engineering: In the municipal pipeline laying projects of major African cities, the 30° tilting bucket (optional configuration) of the SY215 has obvious advantages. It can quickly and accurately excavate ditch shapes that meet the design requirements, improving the efficiency and quality of pipeline laying. At the same time, its flexible operation performance enables the equipment to operate safely in narrow urban streets and complex terrain environments, reducing the impact on the surrounding environment.

(3) Agricultural and Water Conservancy Projects (Important Support for African Agricultural Development)

• Land Reclamation and Farmland Transformation: In large - scale farm projects in agricultural countries such as Ethiopia and Tanzania, the SY215 is used for land reclamation, farmland leveling, and terrace construction. With its powerful power and large - capacity bucket, it can quickly remove surface vegetation, rocks, and other obstacles and level the land, creating good conditions for crop planting. It can reclaim up to 20 hectares of wasteland per day on average, greatly improving agricultural production efficiency.

• Water Conservancy Project Construction: In many water conservancy irrigation projects in Africa, the SY215 is responsible for key tasks such as irrigation canal excavation and reservoir dam construction. With its large excavation depth and precise excavation control, it can excavate regular irrigation channels according to design requirements, ensuring smooth water flow. During the construction of reservoir dams, it can efficiently handle earthwork, carry out dam filling and compaction operations, and guarantee the quality and safety of water conservancy projects.

(4) Forestry and Ecological Projects (Balancing African Ecological Protection and Development)

In forestry development and ecological protection projects in African tropical rainforest areas, the SY215 can be used for opening forest roads, clearing logging residues, and ecological restoration. Its sturdy chassis and good cross - country performance enable it to travel freely in complex forest terrains. By equipping appropriate attachments, such as grapples and breakers, it can perform functions such as tree handling and root crushing, not only meeting the needs of forestry production but also playing an important role in ecological restoration projects, such as land leveling and vegetation restoration.

V. Sales Guarantee System

(1) Strict Pre - sale Inspection

Each Sany SY215 used excavator for sale undergoes a three - stage strict inspection process to ensure reliable equipment quality:

• Preliminary Appearance and Function Inspection: Professional inspectors conduct a comprehensive appearance inspection of the equipment, checking for obvious damage and deformation of components such as the body, boom, and stick. The equipment is started, and basic functions such as excavation, slewing, and traveling are tested to initially determine the overall operation status of the equipment.

• Professional Instrument Inspection: Advanced inspection instruments such as engine analyzers, hydraulic system detectors, and chassis flaw detectors are used to accurately detect and analyze the engine performance, hydraulic system pressure and flow, and chassis component structural strength, obtaining detailed equipment performance parameters.

• Actual Working Condition Test: The equipment is put into a test site that simulates actual working conditions for at least 8 hours of continuous operation testing. Observe the power output, operation stability, fuel consumption, and other performances of the equipment in the real working environment to ensure that the equipment can meet the actual engineering operation requirements.

In addition, the entire inspection process is supervised and certified by the third - party authoritative inspection agency SGS Africa, which issues a detailed inspection report covering the equipment's system inspection data, fault diagnosis results, performance evaluation conclusions, etc., providing you with objective and accurate equipment quality information and making your purchase more reassuring.

(2) Convenient Logistics and Customs Clearance Services

We have established long - term cooperative relationships with many international well - known shipping companies and professional logistics companies to provide you with one - stop logistics solutions, ensuring the safe and fast delivery of equipment:

Customized Transportation Plan: According to your location and needs, a personalized transportation plan is formulated, supporting various transportation methods such as full - container load and less - than - container load. Departing from major Chinese ports such as Shanghai Port and Qingdao Port, it can directly reach major African ports such as Port of Durban, Port of Mombasa, and Port of Lagos. The transportation routes are mature and reliable, and the transportation time can be accurately estimated.