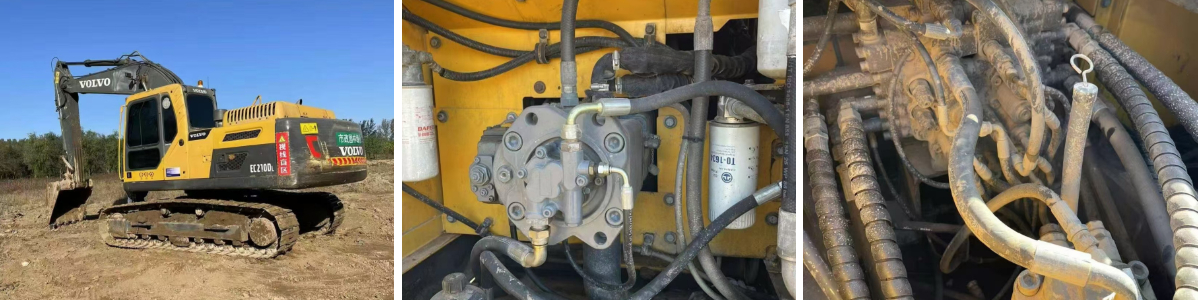

Volvo 210

I. Outstanding Performance with Sufficient Power

Equipped with the Volvo D5E engine, it delivers a total power output of 123kW. Thanks to advanced turbocharging and common rail fuel injection technologies, it can generate high torque even at low speeds, easily handling tasks like excavating hard rocks and large - scale earthmoving. Moreover, it features an intelligent fuel consumption management system.

II. Rigorous Inspection for Quality Assurance

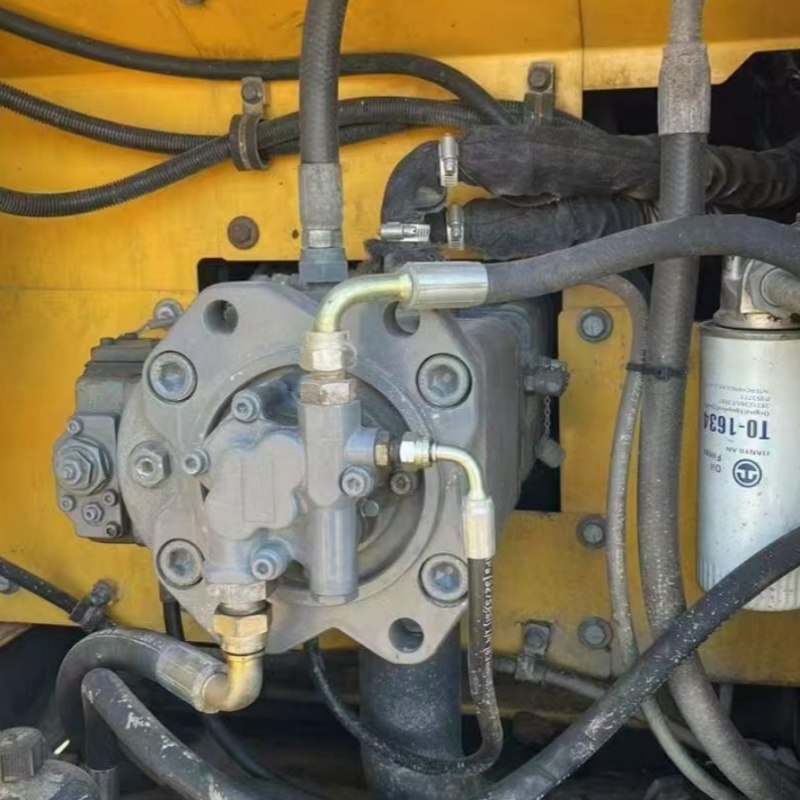

The professional technical team uses Volvo's special "Dig Assist" intelligent inspection system to conduct detailed inspections of key engine indicators, such as the accuracy of the fuel injection system and the working status of the turbocharger. They also conduct in - depth evaluations of the pressure stability, sealing performance, and the performance of hydraulic pumps and control valves of the hydraulic system.

Technical Parameters Demonstrating Strength

Volvo 210 Used Excavator An Efficient and Reliable Engineering Partner The Volvo 210 used excavator has long enjoyed a great reputation in the construction machinery field and plays a crucial role in various engineering projects with its excellent performance.This technology can intelligently distribute the flow of hydraulic oil according to the requirements of different working devices, reducing energy loss. With a bucket digging force of up to 123kN (normal, according to SAE J1179 standard) and an arm digging force of 96kN, combined with a bucket capacity ranging from 0.5 to 1.25 cubic meters (varying with different configurations), it can improve the operation efficiency by 10% - 15%, whether it is fine excavation for small - scale projects or material handling for large - scale projects. After professional in - depth maintenance, the overall performance of the Volvo 210 used excavator can be restored to more than 80% of that of a new machine (depending on the actual vehicle condition), effectively extending the equipment's service life and reducing customers' equipment procurement and long - term use costs.

Parameter Item | Detailed Data | Application Advantages |

Operating Weight of the Whole Machine | 20500 - 22100kg (varies by version) | The moderate weight endows the equipment with good stability and maneuverability at various construction sites. It remains stable during operation, reducing sway, and is convenient for transfer, improving equipment utilization. |

Engine Model | Volvo D5E, etc. (varies by model) | With advanced fuel injection and turbocharging technologies, it offers strong power and good fuel economy, ensuring efficient operation while reducing fuel costs, suitable for long - term continuous operation. |

Rated Power | Approximately 123kW (varies by engine model) | Provides sufficient power for actions such as digging, lifting, and slewing. It can maintain stable performance under heavy loads and harsh conditions, ensuring project progress. |

Standard Bucket Capacity | 0.5 - 1.25m³ (varies by configuration) | The large - capacity bucket can load more materials at a time, reducing the number of handling trips and significantly improving the handling efficiency of earth, ore, and other materials, suitable for large - scale projects. |

Maximum Digging Radius | 9930 - 9940mm (varies by model) | In large - scale site leveling, river dredging, and other operations, the large digging radius can cover a wider area, reducing the frequency of equipment movement and improving operation efficiency. |

Maximum Digging Depth | 6730 - 6744mm (varies by model) | Meets the requirements of projects with high digging depth requirements, such as deep foundation pit excavation and tunnel digging, ensuring that construction meets design standards. |

Maximum Digging Height | Approximately 9450mm (varies by model) | Suitable for tasks such as material loading and high - slope trimming. It can easily load materials onto taller transport vehicles and precisely trim high slopes. |

Maximum Dumping Height | Approximately 6650mm (varies by model) | Facilitates dumping materials onto taller stockpiles or transport equipment, performing well in high - dumping scenarios such as mines and ports. |

Swing Speed | Approximately 11.6rpm (varies by model) | The fast swing speed enables the equipment to quickly switch between digging, loading, and unloading actions, shortening the single operation cycle time and improving overall operation efficiency. |

Travel Speed (High/Low) | (varies by model, e.g., high speed can reach X km/h, low speed can reach Y km/h) | The high - speed mode is conducive to fast transfer within the construction site, saving time; the low - speed mode provides strong traction, suitable for soft ground or climbing. |

Track Ground Contact Pressure | (specific value varies by model, e.g., Z kg/cm² for a certain model) | The low ground contact pressure reduces the pressure on the ground, preventing the equipment from sinking on soft ground and ensuring smooth operation and passage while protecting the ground. |

Climbing Ability | (specific angle varies by model, e.g., A° for a certain model) | The strong climbing performance allows the equipment to move freely up and down slopes in complex terrain construction sites, expanding the operation range. |

IV. Adaptable to Various Working Conditions with Wide Applications

(1) Mining

In the African mining field, the Volvo 210 used excavator also performs exceptionally well. In a gold mining project in South Africa, due to the complex terrain and high hardness of the ore in the mining area, there are extremely high requirements for the equipment's digging force and durability. After multiple Volvo 210 used excavators were put into use, with their strong digging force, they easily broke hard ores. Combined with large - capacity buckets, they efficiently loaded and transported the ores, increasing the daily ore processing volume by 20% and helping the project complete the phased mining target ahead of schedule. Their excellent durability also withstood the test of the harsh mining environment, reducing equipment failure downtime and lowering operating costs.

(2) Earthwork

In the urban expansion project in Nairobi, Kenya, a large amount of land leveling and foundation excavation work urgently required efficient equipment. The Volvo 210 used excavator, with its precise hydraulic control and large - capacity bucket, operated flexibly in the narrow urban construction environment. It not only efficiently completed earthwork excavation and handling tasks but also saved 12% of fuel costs through the intelligent fuel consumption management system. The project leader stated that the efficient operation of the Volvo 210 saved a lot of time and costs for the project, ensuring the timely delivery of the project.

(3) Infrastructure Construction

In the railway construction project in Ethiopia, facing complex terrains such as plateaus and mountains, the advantages of the Volvo 210 used excavator were fully demonstrated. Its strong climbing ability and stable travel system enabled it to move freely in rugged mountainous areas, successfully completing the excavation and trimming of the railway subgrade. At the same time, the "flow sharing" technology allowed the excavator to precisely control the digging force and operation speed during fine culvert excavation, ensuring the project quality. In this project, the operation efficiency of the Volvo 210 was 15% higher than that of similar equipment, winning high praise from the construction party.

V. Export Advantages with Worry - Free Services

(1) Authoritative Certifications for Quality Guarantee

Each exported Volvo 210 used excavator has passed a number of international authoritative certifications. For example, the EU CE certification strictly adheres to European safety, health, and environmental protection standards, comprehensively testing the equipment's safety, environmental protection, reliability, and other aspects. There is also the North American CSA certification, which is highly recognized in North America, ensuring that the equipment complies with local regulatory requirements. In addition, it has obtained certifications from the African Organization for Standardization (ARSO), the Standards Organization of Nigeria (SON), the Kenya Bureau of Standards (KEBS), and other major African countries' access certifications.

In addition, Volvo also has the unique "Environmental Product Declaration (EPD)" certification. This certification details the environmental impact data of the product throughout its entire life cycle, from raw material acquisition, production, transportation, use, to final recycling, further highlighting the product's outstanding performance in environmental protection and enabling customers to purchase and use it with confidence.

(2) Global Logistics Network for Efficient Delivery

We have established in - depth cooperation with global well - known logistics enterprises to build a global logistics and transportation network. For the Volvo 210 used excavator, which is large in size and heavy in weight, professional transportation solutions are customized: special containers, professional transport vehicles, and reinforcement binding technologies are used to ensure the stable and safe transportation of the equipment during sea, land, and air transportation. Diversified transportation services such as door - to - door, port - to - port, and terminal - to - terminal are provided to meet the needs of different customers. Shipping from major Chinese ports to major ports around the world, the transportation time is reasonably arranged according to the destination. At the same time, real - time logistics tracking services are provided. Customers can query the transportation status of the equipment at any time through mobile phones, computers, and other devices to ensure the timely and safe delivery of the equipment.

(3) Localized After - sales Service for Considerate Support

Professional after - sales service centers have been established in many countries and regions around the world. The experienced and highly skilled multilingual after - sales team, with technicians proficient in English, French, Spanish, Arabic, and other languages, can provide timely and accurate technical support and after - sales services to customers in different countries and regions. A 7×24 - hour global technical support hotline is provided, and engineers can quickly locate equipment faults through the remote diagnostic system. For emergency faults, we promise to initiate global on - site service within the specified time to carry out repairs in a timely manner.

In addition to stocking a large number of genuine Volvo original parts in each after - sales service center to ensure that the parts supply timeliness rate reaches over 90%, and being able to achieve fast global delivery of emergency parts through cooperation with international express giants, we also provide the unique "Volvo CareTrack" remote management service. Customers can view real - time information such as the equipment's working hours, fuel consumption, and fault warnings through a mobile APP or computer terminal, which is convenient for planning maintenance in advance and further reducing equipment operation costs, allowing customers to use the equipment without worries.

VI. Convenient Ordering for Win - Win Cooperation

(1) Exclusive Quotations with Generous Discounts

We provide one - to - one customized quotations according to customers' purchase quantities, equipment configuration requirements, and delivery locations. For bulk purchase orders, greater price discounts are offered to help customers obtain high - quality equipment at the most economical prices. At the same time, flexible purchasing options such as lease - purchase and trade - in are introduced, and cooperation with financial institutions is carried out to provide low - interest loan purchasing services to meet customers' diverse funding needs.

(2) Diverse Payment Methods for Secure and Convenient Transactions

A variety of payment methods are supported, including telegraphic transfer (T/T), letter of credit (L/C), credit card payment, mobile payment (such as the internationally common PayPal), etc., fully meeting the payment habits of different customers. For foreign exchange control issues in different countries, compliant cross - border payment solutions are provided to simplify the payment process and reduce payment risks, ensuring the safe and convenient progress of transactions.

(3) Fast Delivery for Timely Response

After the order is confirmed, delivery will be arranged within 7 - 10 days (subject to the actual situation). Express delivery services are available. By paying an additional fee, the delivery cycle can be shortened to 3 - 5 days to meet the needs of customers' urgent projects, enabling the equipment to be put into use as soon as possible and creating value for customers.

Contact our sales team now to obtain high - definition video cases of the Volvo 210 used excavator in engineering operations around the world, detailed technical manuals, and make an appointment for on - site inspections and equipment test drives. Experience its excellent performance and high cost - effectiveness firsthand and join hands with us to embark on a new journey of efficient engineering construction!